How Should You Mount Your Vibration Sensor?

Correctly mounting a vibration sensor is one of the most important steps in achieving accurate and reliable monitoring data. Even the highest-quality sensor will deliver poor results if it is incorrectly installed. Understanding how to mount vibration sensors properly ensures meaningful data, supports predictive maintenance strategies, and helps engineers make confident maintenance decisions based on real machine data.

Why Correct Mounting Matters

The way a vibration sensor is mounted has a direct impact on the quality and reliability of the data it captures. Poor mounting can introduce errors that lead to misdiagnosis, unnecessary maintenance, or missed early warning signs.

- Accuracy of vibration data

A securely mounted sensor maintains consistent contact with the machine surface, allowing vibration signals to transfer accurately from the asset to the sensor. Loose or unstable mounting can dampen high-frequency signals, masking early-stage faults and other developing issues. - Preventing false readings and unnecessary maintenance

Incorrect mounting methods can introduce resonance, signal distortion, or interference from surrounding structures. This can result in misleading vibration readings, potentially triggering unnecessary inspections or repairs based on incorrect data. - Supporting predictive maintenance strategies

Predictive maintenance relies on stable, repeatable measurements over time. Correct sensor mounting ensures consistency in data trends, enabling maintenance teams to detect subtle changes in machine condition and take action before failures occur.

Best Practices for Mounting Vibration Sensors

Following proven mounting techniques is essential for obtaining high-quality vibration data in industrial environments.

- Recommended techniques

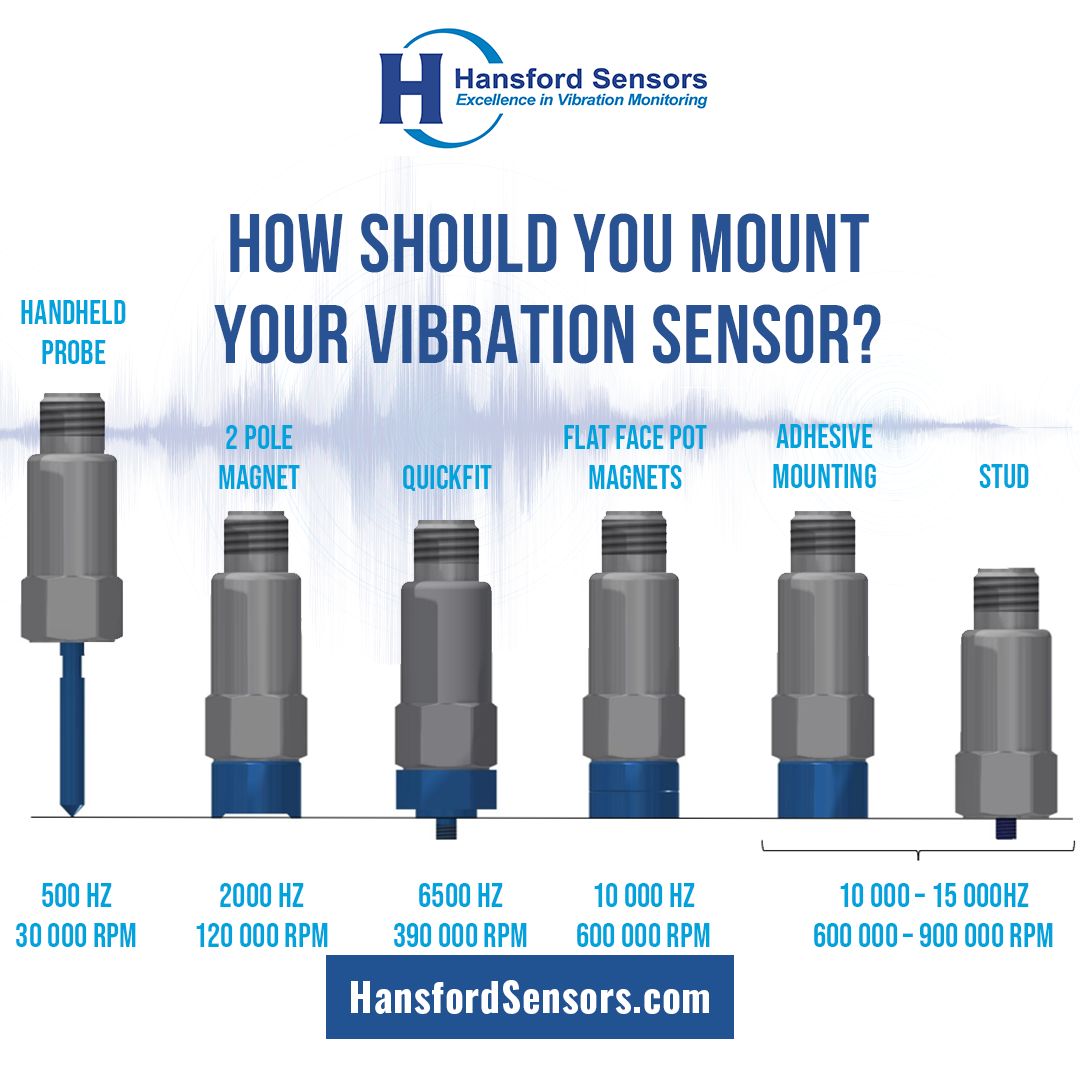

The preferred mounting method is a permanently installed, stud-mounted sensor directly fixed to the machine surface. This provides the best mechanical coupling and widest frequency response. Where permanent mounting is not possible, alternative methods such as adhesive mounting or magnetic bases may be used, though with some limitations. - Correct positioning

Sensors should be mounted as close as possible to the source of vibration, typically near bearings, gear meshes, or drive components. Sensor placement should be perpendicular to the axis of rotation where possible, ensuring the sensor captures meaningful vibration energy related to machine condition. - Surface preparation and stability tips

The mounting surface should be flat, clean, and free from paint, grease, or corrosion. A smooth, machined surface ensures optimal contact and signal transmission. Spot facing tools are often used to create a flat mounting area on curved or uneven machine housings, improving stability and measurement accuracy.

Hansford Recommendations for Reliable Installation

Drawing on decades of vibration monitoring experience, Hansford Sensors recommends a practical, engineering-led approach to sensor installation.

- Common mistakes to avoid in industrial settings

Frequent issues include mounting sensors on thin guards instead of solid machine housings, using loose adapters, or relying on temporary mounting for long-term monitoring. These practices can compromise data quality and reduce confidence in the collected vibration trend data. - Suggested Hansford products

Hansford Sensors’ industrial accelerometers, such as the HS-100 Series, are designed for stud mounting and robust long-term installation. Complementary accessories, including mounting studs, isolation adapters, and spot facing kits, help ensure correct installation across a wide range of machinery and environments.

Quick checklist for engineers and maintenance teams

- Mount the sensor directly to a solid machine surface

- Ensure the mounting area is flat, clean, and unpainted

- Position the sensor close to the vibration source

- Use the correct mounting hardware and torque settings

- Verify signal stability after installation

Correctly understanding how to mount vibration sensors is a fundamental step in achieving reliable condition monitoring results. By following best practices and using appropriate installation methods, maintenance teams can maximise data accuracy, support predictive maintenance programmes, and protect critical assets with confidence.