Enhancing Efficiency and Reliability in the Paper & Pulp Industry with Vibration Monitoring

For use in pumps, fans, gearboxes and motors in paper and pulp mills and production lines

Optimised Performance for Paper Mills with Hansford Sensors

The paper and pulp industry operates in an environment where machinery must endure continuous heavy loads, high-speed operations, and exposure to moisture and dust. Maintaining uptime and operational efficiency is critical, as unplanned breakdowns lead to significant production losses and increased maintenance costs.

At Hansford Sensors, we provide industry-leading vibration monitoring solutions to help paper mills and pulp processing plants detect early signs of mechanical wear, prevent equipment failure, and implement predictive maintenance strategies that optimise production efficiency.

The Importance of Vibration Monitoring in the Paper & Pulp Industry

Paper manufacturing is a complex process that involves multiple stages, each relying on heavy-duty rotating machinery. These machines are susceptible to mechanical issues such as misalignment, imbalance, bearing wear, and resonance, all of which can lead to costly downtime if left unchecked.

Key machinery in paper mills includes:

- Pumps – Essential for moving pulp slurry and water throughout the mill. Cavitation, imbalance, and bearing wear can lead to inefficient operation and unexpected failures.

- Fans & Blowers – Used for air circulation and drying processes. High-speed operation means they are prone to vibration due to imbalance or misalignment.

- Gearboxes – Found in paper machines and conveyors, gearboxes must be monitored for early signs of wear, lubrication issues, and misalignment.

- Motors & Drives – The heart of any production line, motors are vulnerable to bearing degradation, overheating, and misalignment, all of which can be detected through vibration analysis.

- Press Sections & Dryers – Critical for achieving optimal moisture content, these sections require consistent monitoring to detect mechanical looseness and uneven roller pressure.

By implementing vibration monitoring solutions, paper mills can significantly reduce unplanned maintenance, enhance productivity, and extend the lifespan of critical assets.

Hansford Sensors: Precision Vibration Monitoring for Paper Mills

Hansford Sensors is a trusted partner for the global paper and pulp industry, delivering high-performance industrial vibration sensors that enable proactive maintenance and improved machine reliability.

Why Choose Hansford Sensors?

- Early Fault Detection – Identify signs of imbalance, misalignment, and bearing wear before failures occur.

- Reduced Downtime – Implement predictive maintenance strategies that keep production running efficiently.

- Increased Operational Efficiency – Ensure motors, gearboxes, and fans operate at peak performance.

- Cost Savings – Minimise maintenance expenses and extend the lifespan of critical equipment.

- Enhanced Safety & Compliance – Reduce mechanical failures and maintain compliance with industry regulations.

Vibration Sensor Solutions for the Paper & Pulp Industry

Hansford Sensors provides a range of reliable, high-quality vibration monitoring solutions tailored for the paper and pulp industry, including:

- HS-100 Series Industrial Accelerometers – Robust stainless-steel sensors designed for harsh operating conditions, available in both top- and side-entry models.

- HS-420 4-20mA Sensors – Ideal for integration into PLC systems, enabling real-time monitoring and automated fault alerts.

- HS-535 Triple Output Accelerometers – Advanced multi-output sensors capable of monitoring bearing condition, imbalance, and misalignment simultaneously.

- HS-510 Local Monitoring Modules – Provide real-time vibration analysis and relay-based alarms for on-site equipment protection.

- HS-570 & HS-580 Enclosures – Industrial-grade enclosures designed to protect sensors from moisture, dust, and extreme temperatures.

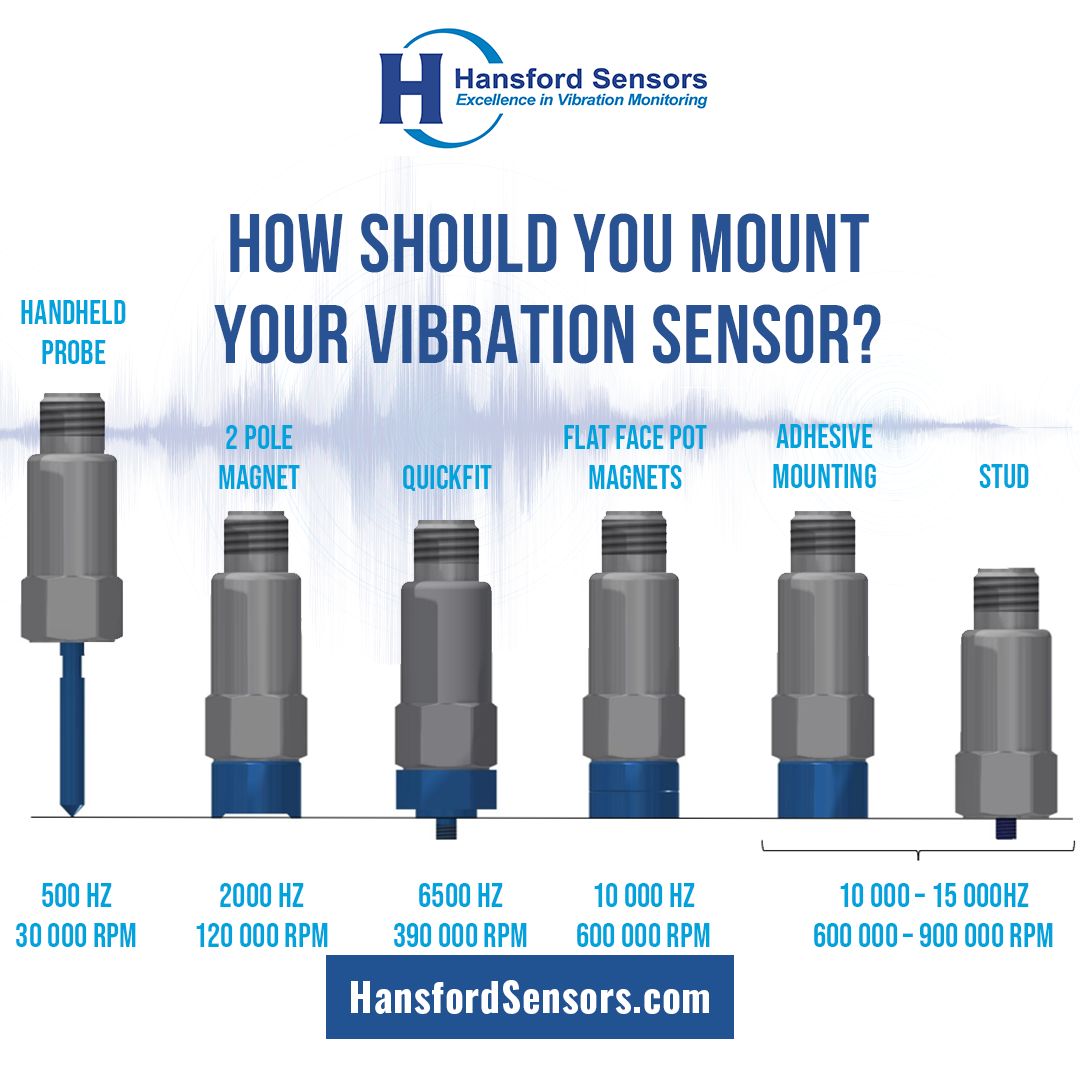

These solutions support both online and offline vibration monitoring, allowing continuous condition monitoring or periodic inspections using handheld data collectors.

How Vibration Monitoring Enhances Paper Mill Performance

- Predictive Maintenance: Detect issues before they escalate, preventing catastrophic failures and reducing downtime.

- Improved Energy Efficiency: Properly maintained machines operate with less friction and energy loss, reducing operational costs.

- Optimised Production Output: Reliable machinery ensures a consistent and uninterrupted manufacturing process, leading to higher productivity.

- Extended Equipment Lifespan: By preventing excessive wear and tear, vibration monitoring extends the service life of motors, pumps, and rollers.

- Regulatory Compliance: Monitoring critical equipment helps mills comply with industry safety and operational standards, reducing risk and liability.

Trusted by Leading Paper & Pulp Manufacturers Worldwide

Hansford Sensors has a proven track record of delivering precision-engineered vibration monitoring solutions to paper mills and pulp processing plants across the globe. Our expertise in industrial condition monitoring helps manufacturers maximise uptime, reduce maintenance costs, and enhance overall efficiency.

Get in touch with our team today to discuss your specific requirements and discover how Hansford Sensors can enhance your plant’s performance.

Typical solutions for the Paper & Pulp Industry

Recommended Articles

Guides and Articles