Single Axis vs Triaxial Accelerometers

The question of Triaxial Accelerometers Vs Single axis takes in many factors including cost, accuracy, ease of data collection and more. Below are some facts and illustrations to help you decide which is better for your specific application.

Our range includes world class examples of both single axis and Triaxial Accelerometers, as well as a huge variety of 100mV/g accelerometers and 4-20mA transmitters. If you’d like more information on our Single and Triaxial Accelerometers please don’t hesitate to get in touch with our team to discuss your needs and the requirements of your specific application or industry.

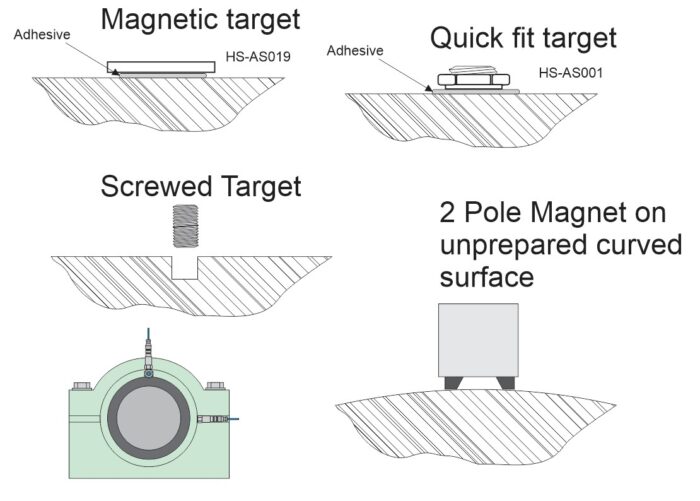

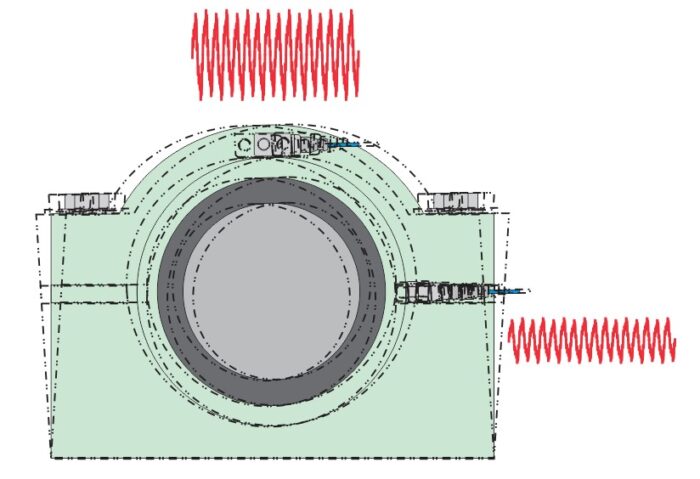

Fig.1 Traditional methods for taking data using a single channel data collector is to mount the sensor using a magnet in the X, Y and Z axis.

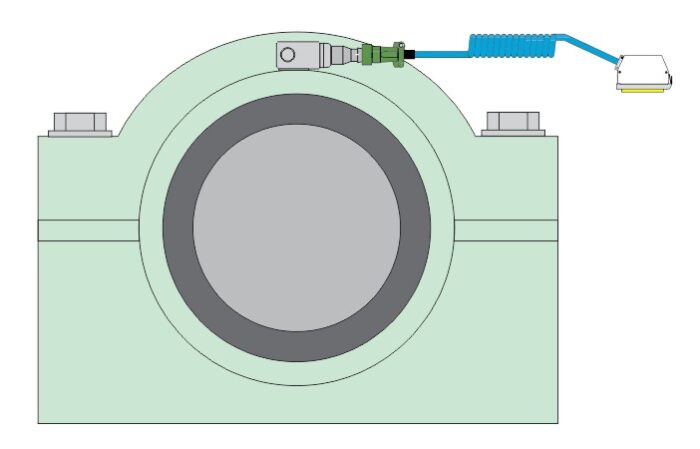

Fig.3 The motivator for fitting triaxial sensors is where portable data collectors are used. Instead of having to prepare three sites on each machine, and take three separate site readings and wait for the settling time at each location, one triaxial sensor alone can achieve all three results. In the right application where access is restricted, triaxial sensors can make for a simple install and save valuable time.

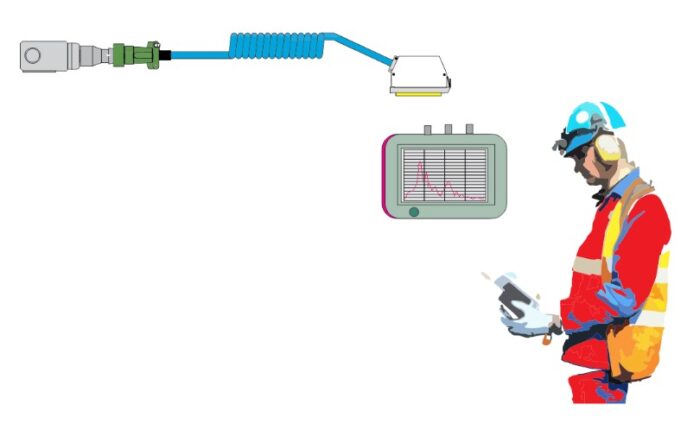

Fig.4 Data collectors with 4 channel capability are able to take the signal from each channel of a triaxial accelerometer simultaneously. Since all axis are located at the same point and taken simultaneously, valuable phase information is preserved and can be used in advanced vibration analysis.

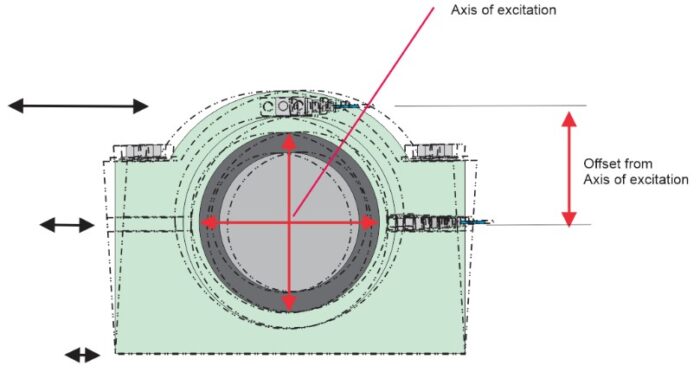

Fig.5 Vibration data can be different depending on where the vibration is measured. The less direct the path between the exciting element (shaft rotating in bearing) the more attenuated the data. This is more of a problem for high frequency data (gear mesh, roller element bearings) than it is for lower frequency data.

Fig.6 In addition if the bearing case is less stiff or has soft feet then vibration amplitudes maybe distorted or amplified. This is caused by the cantilever effect of having the x axis offset from the axis of excitation.

Fig.6

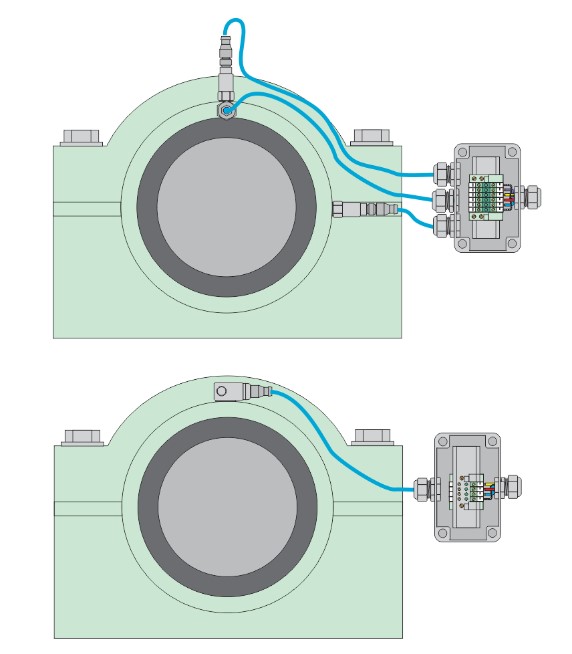

Fig.7 For permanently installed systems, the triaxial sensor may provide cost savings for cabling. Installation consists of running only one cable as opposed to three. This maybe significant if the junction box is not located locally.

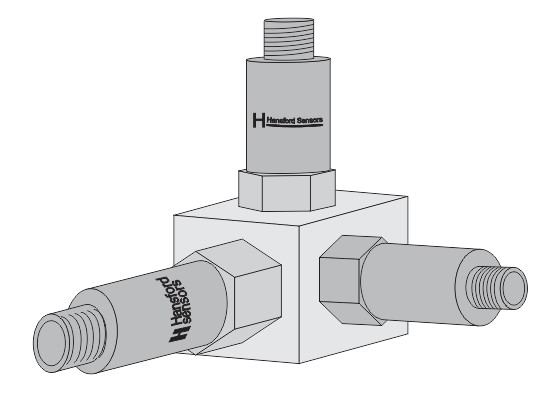

Fig.8 Triaxial sensors are higher cost than three single axis sensors. If local machine topography makes a triaxial attractive then one solution is to mount three single sensors on a triaxial mounting block. As loop powered sensors are never used with data collectors, triaxial 4-20mA sensors are much less relevant. In applications requiring orthogonal mounted sensors a triaxial mounting block can also be used.