Route Measurement vs Online Vibration Monitoring: Choosing the Right Machine Monitoring Method

In industrial environments, machine monitoring is critical to maintaining operational efficiency, reducing downtime, and extending the life of equipment. Two widely used approaches for tracking machine health are route-based vibration measurement and online vibration monitoring systems. Each method offers unique advantages and challenges depending on the needs of your facility.

Below, we compare these two strategies to help you determine the most effective monitoring solution for your industrial maintenance program.

What is Route-Based Vibration Measurement?

Route measurement involves technicians periodically visiting machines to manually collect vibration data using portable data collectors. It’s a traditional and well-established practice that still plays a vital role in many facilities.

Advantages of Route Measurement

- Cost-Effective

Route measurement requires less upfront investment, as it avoids the need for continuous monitoring hardware and networking infrastructure. - Flexible Monitoring

Technicians can tailor routes to focus on critical equipment, seasonal operations, or newly installed machinery. - Simple to Implement

With no need for complex integration, route-based monitoring is easy to deploy, especially in smaller facilities or those just starting a condition monitoring program.

?️ Explore Hansford Sensors’ route measurement products:

HS-SE-M Switching Enclosure

Mild Steel

HS-AA002-1-2 Bracket

90° Bracket with 2 x BNC Bulkhead Socket

Limitations of Route Measurement

- Time consuming: manually collecting data can be time consuming and requires regular site visits.

- Limited data frequency: Data is only collected at certain times, meaning potential problems can go undetected between measurements.

- Subjectivity: The interpretation of data can depend on the experience of the technician, which can lead to inconsistencies.

What is Online Vibration Monitoring?

Online monitoring systems use permanently installed vibration sensors to capture and transmit data continuously. This method supports real-time machine condition monitoring and advanced diagnostics.

Advantages of Online Vibration Monitoring

1. Real-time monitoring: online systems allow continuous monitoring of the machine’s condition, enabling an immediate response to potential problems.

2. Data analysis: the data collected can be analysed in real time to identify trends and develop predictive maintenance strategies.

3. Automation: Many online systems offer automated al

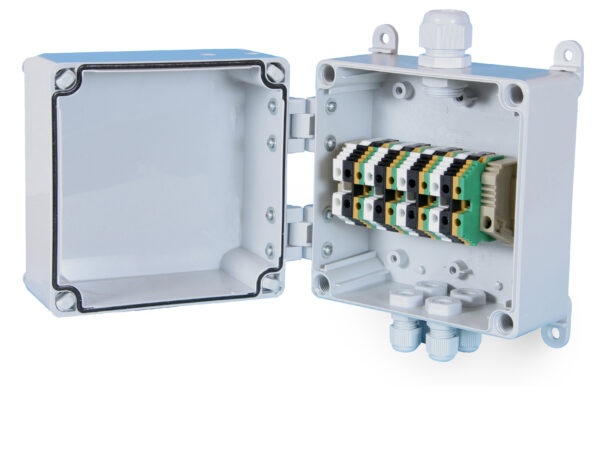

HS-JE Junction Enclosure

Polycarbonate