Energy demand on the rise

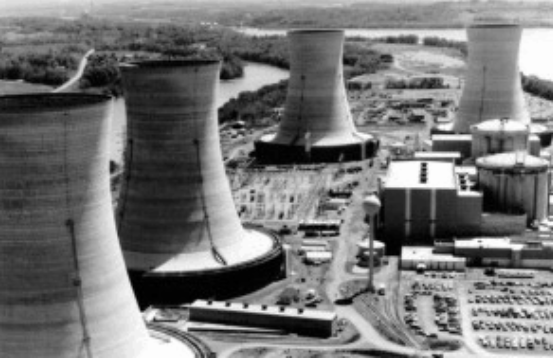

The IEA has reported, in its World Energy Outlook 2013, that global energy demand will rise by one third by 2035. With this rising demand for energy resources coupled with ever-increasing demands for industry to produce cleaner, more efficient energy, the pressure to maximise efficiency in cooling towers has never been higher.

The challenge for providers is to maintain safety while focussing on low-cost running of each plant. This is where reliable condition monitoring and predictive maintenance can have significant benefits, both in terms of saving money and in ensuring that equipment is safe and stable at all times.

Vibration monitoring for example identifies such urgent issues as a component wearing to the point of failure, enabling engineers to predict impending failure, schedule repairs and tackle issues in advance before the spectre of downtime damages profitability. This technology is especially critical within power station cooling towers, because they must remain operational at all times to maximise generation capacity.

Within each cooling tower is a large fan system, providing forced air to the heat exchangers. The fans are typically several metres wide and, along with the drive motors, gearboxes and associated linkages and control mechanisms, are prone to vibration, either through misalignment or wear.

Vibration monitoring technology helps engineers to manage systems and exercise long term cost control across power generation plants. The level of vibration in rotary or reciprocating motion machinery can be swiftly ascertained at the point of use, while measurements in excess of safe limits can trigger alert or danger alarms to indicate potential bearing damage. Today’s hand-held data collection devices have simplified the gathering, analysis, use and sharing of machine condition data, either in conjunction with predictive maintenance software systems or as standalone units with the capability to provide on-the-spot advice.

In cooling towers, there are several issues for the vibration analyst to consider but, increasingly, many solutions to the challenges posed. In cooling towers there are various issues that vibration analysts need to consider. Of these, access to gearboxes and motors can be particularly challenging, making the ability to monitor vibration remotely of considerable benefit.