Efficiency in food production

2012 has been something of a roller coaster for many sectors of industry. Although food production companies have been insulated from some of the uncertainties that have beset the economy, it’s still been a challenging year, and 2013 does not look as if it’s going to be much different. Factors such as cost control – at all stages of the production process – productivity and machine availability are going to remain as key requirements for food companies that want to protect their margins.

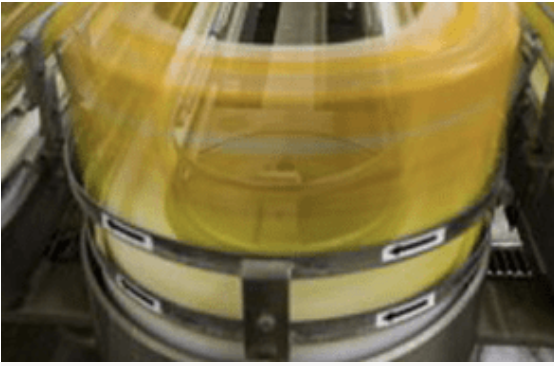

At an operational or factory level this makes an effective maintenance strategy essential – and the measurement of vibration plays a key part in such a strategy. Our vibration monitoring and analysis systems are designed for use on all rotating shafts, pumps, motors, fans and gearboxes, and will detect the smallest fluctuations in operating conditions. This enables engineers to identify problems of wear or imbalance before they impact on machine efficiencies, including increased energy consumption, and to forward plan appropriate maintenance or repairs at a time that minimises disruption to the business.

Even at times of economic growth and stability, you should review your maintenance strategies on a regular basis, to ensure for example that you are using the most up to sensors and monitoring techniques. In the times through which we are currently living, when every aspect of running a food production business is under constant pressure to perform, the need to maximise the return from your production systems is critical – and vibration monitoring is key to that process.