Application Guide to Vibration Monitoring on Vertical Pumps

Using Wired IEPE Vibration Accelerometers

Introduction

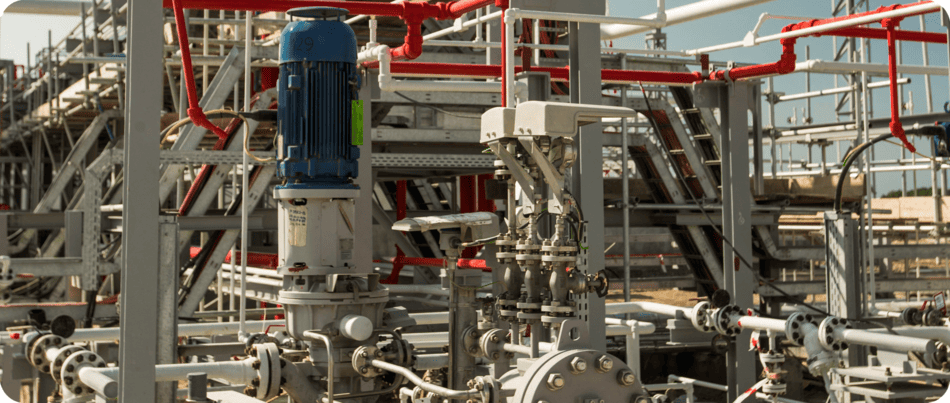

Vibration monitoring is a crucial tool for diagnosing and preventing failures in vertical pumps. These pumps are commonly used in industries such as water treatment, power generation, oil and gas, and chemical processing.

Wired IEPE (Integrated Electronics Piezo Electric) accelerometers provide high fidelity vibration data, enabling predictive maintenance and early fault detection.

Common Problems Diagnosed Through Vibration Analysis

Vertical pumps experience a range of mechanical and operational issues that can be detected through vibration monitoring, including:

- Misalignment

Improper alignment between the motor and pump can lead to excessive vibration, reducing efficiency and causing premature wear. - Unbalance

Unbalanced impellers or motor rotors create high radial forces, leading to increased vibration levels. - Bearing Defects

Wear, contamination, or lubrication issues can lead to bearing degradation, detected by high frequency vibration analysis. - Resonance Issues

Structural or foundation related resonance can amplify vibration, causing damage to components. - Cavitation

Hydraulic issues such as cavitation produce specific vibration patterns that can be analysed to prevent impeller damage. - Looseness

Loose components or fasteners can generate excessive movement and abnormal vibration signals.

Vibration Sensor Mounting Locations

Proper sensor placement is essential for obtaining accurate and useful vibration data. The key locations for mounting wired IEPE accelerometers on vertical pumps include:

Motor Bearings (Upper and Lower)

Radial and Axial Measurements

Purpose

Detect motor related faults such as imbalance, misalignment, and bearing wear.

Mounting

Sensors should be placed as close as possible to the bearing housings, with one positioned radially and one axially to capture comprehensive vibration data.

Pump Bearings (Upper and Lower)

Radial and Axial Measurements

Purpose

Identify pump bearing wear, unbalance, and shaft related issues.

Mounting

Place accelerometers on the bearing housing, with one sensor in the radial direction and another in the axial direction.

Pump Casing (Middle Section)

Radial Measurements

Purpose

Detect structural vibrations, looseness, and resonance.

Mounting

Securely attach the accelerometer to the pump casing near the middle section of the pump column.

Baseplate or Mounting Structure

Vertical and Horizontal Measurements

Purpose

Monitor foundation related issues such as resonance or looseness.

Mounting

Install sensors on the pump baseplate or supporting structure to detect excessive vibration caused by foundation problems.