Addressing Frame Vibrations: Causes, Measurement, and Solutions

Introduction

Machine vibrations are often inevitable due to rotating components, operational loads, and dynamic forces. However, excessive or abnormal vibrations caused by improper mounting can lead to structural damage, reduced lifespan, and operational inefficiency.

The frame of a machine is particularly vulnerable because it serves as the structural support and is directly influenced by how the machine is mounted.

This white paper delves into the phenomenon of frame vibrations, focusing on:

- The root causes associated with mounting issues

- The use of accelerometers for precise vibration measurements

- Strategies for diagnosing and addressing frame vibration problems

Causes of Frame Vibrations

Frame vibrations due to mounting problems typically arise from:

Resonance

When the natural frequency of the machine’s frame coincides with the operational frequency, resonance occurs, amplifying vibrations. Poorly designed or installed mounts can exacerbate this problem.

Improper Mounting Surfaces

Uneven or non rigid mounting surfaces lead to uneven force distribution, which can cause structural deformation and increased vibration.

Insufficient Damping

Inadequate damping materials or mechanisms fail to absorb vibrational energy, resulting in excessive transmission of vibrations to the frame.

Misalignment

Misalignment between the machine and its mounts creates unbalanced forces that induce frame vibrations. This issue often arises from improper installation or wear over time.

Dynamic Imbalance

Imbalance in rotating components generates forces that are transferred to the frame, magnified by poor mounting stability.

Loose or Worn Fasteners

Loose or degraded mounting hardware can reduce the rigidity of the system, making the frame more susceptible to vibrational excitation.

Measurement Techniques Using Accelerometers

Why Accelerometers

Accelerometers are highly effective tools for vibration measurement due to their precision, wide frequency range, and adaptability. They measure acceleration, velocity, or displacement, providing insights into the vibration characteristics of the machine’s frame.

Placement of Accelerometers

- Frame mounting points to measure vibrations directly transmitted from the machine

- Critical structural locations to detect deformation or resonance points

- In line to force transmission paths to capture vibrations traveling through mounts or fasteners

Measurement Parameters

- Frequency spectrum identifying resonance frequencies. The easiest way is to perform a measurement during machine run up or make a bump test

- Amplitude quantifying the severity of vibrations. Higher levels are the reason to look for source and cause

- Phase relationships

Methodology

- Baseline measurements recorded under ideal conditions

- Operational testing during typical machine operation to identify deviations

- Mounting analysis by testing different mounting configurations to isolate the problem

- Comparative analysis using data compared with industry standards or manufacturer specifications

- The easiest way is to perform a measurement during machine run up or make a bump test

- Comparing vibration of the frame to machine case enables understanding if they move together or if the connection is loose and vibration signals are out of phase

Diagnosing the Problem

- Visual inspection to identify obvious signs of improper mounting such as uneven surfaces or loose hardware

- Data analysis using accelerometer data to pinpoint high vibration zones and frequencies

- Finite element modeling to simulate frame dynamics and predict vibration behaviour

Mitigation Strategies

- Improving mount design using vibration isolating materials or structures

- Optimising installation by ensuring even and rigid mounting surfaces with proper alignment

- Adding damping through damping pads, rubber mounts, or tuned mass dampers

- Resonance avoidance by adjusting operational speeds or modifying frame stiffness to shift natural frequencies

- Maintenance through regular inspection and replacement of worn or damaged mounting hardware

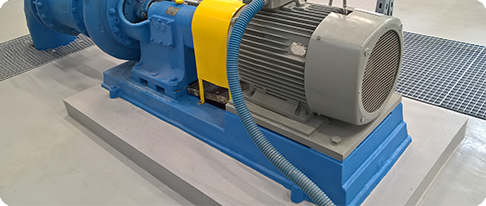

Application Example

A manufacturing facility experienced abnormal vibrations in a pump frame. Measurements with piezoelectric accelerometers revealed a peak vibration amplitude at 20 hertz, corresponding to the frame’s natural frequency.

Analysis showed uneven mounting surfaces and insufficient damping. After installing vibration isolating pads and realigning the mounts, vibrations were reduced by seventy five percent, improving operational stability and extending machine life.

Conclusion

Frame vibrations due to mounting problems can significantly impact machine performance and durability. Understanding the causes and using accelerometers for precise measurement enables effective diagnosis and mitigation.

By addressing mounting issues proactively, industries can ensure smoother operation, longer equipment life, and safer working environments.

Support

With offices worldwide, Hansford Sensors can provide customer support regardless of location. Fully trained staff are available to assist with any technical questions.